Online Engineering Service

C3P Online Engineering Service (OES) enable you to effectively verify selected manufacture processes. At the first phase, we provide the online simulation service for high pressure die casting process. Our service will help you to avoid expensive trial and error processes on real prototypes during the product and mould development cycle.

If you do not have the possibility to do the simulation by yourself, and you wish to get a solution for your casting problem, we are happy to offer you simulations as a service. Service simulations are often the most cost-effective means to get quick solutions for casting problems in small foundries or urgent projects.

The Online Engineering Service (OES) can be used to solve various problems in existing or new castings in those foundries that not yet have their own software. Simulation Service is an inexpensive way to locate problem areas and identify reasons for problems. Different casting solutions for the problem can be simulated quickly. Designing suitable casting system will be faster and expensive test castings can be avoided in the foundry.

Form the results of online engineering service, are based on multi-year experience in engineering service and support with the industrially validated C3P software.

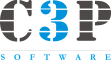

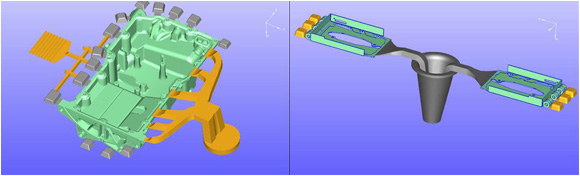

Service Simulation Results:

- Mold filling animations

- Solidification animations

- Solidification times and directions

- Shrinkage

- Hot spots

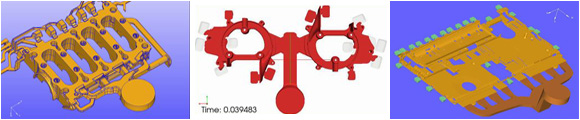

- Better understanding for what really happens during casting process

- Helps to identify problem areas and the reasons for problems

- Faster and easier gating system design; possibility to try several ideas fast

- Helps in deciding the optimal casting system and materials

- Shortened lead time, increased production

- Less wastage and scrap castings improve product quality

- Savings in time, work, materials and energy

To order a service simulation, please download simulation order form, fill it and email it back to us (oes@c3p-group.com ) and send your CAD file and related data file to oes@c3p-group.com.

Payment methods: After received your simulation order form, the online engineering service department will contact you for detail.

Online Engineering Service Packages

Package 1: Basic upfront die casting analysis

Simulated Casting process: High Pressure Die Casting (HPDC)

Pre-existed data:

- Initial gating system was designed by client

- 3D existed casting part with gating system and overflow in STEP, IGES or STL format, STEP data is better

- Filling the simulation order form

- General shapes of casts and simple gating system

Service Charge: USD 2,000.00

Package 2: complex upfront die casting analysis

Simulated Casting process: High Pressure Die Casting (HPDC)

Pre-existed data:

- Initial gating system was designed by client

- 3D existed casting part with gating system and overflow in STEP, IGES or STL format, STEP data is better

- Filling the simulation order form

- Maximum 4 casts in one cavity and more complex gating system

Service Charge: USD 3,000.00

Package 3: advance upfront die casting analysis

Simulated Casting process: High Pressure Die Casting (HPDC)

Pre-existed data:

- No 3D Initial gating system, but client provides some basic ideas of the gating system

- 3D existed casting part without gating system and overflow in STEP, IGES or STL format, STEP data is better

- Filling the simulation order form

- Maximum 4 casts in one cavity

Service Charge: USD 4,000.00

Output of the analysis:

Standard output is the Microsoft PowerPoint format report with eventual problems description plus animations.

Remark:

Mentioned costs are guaranteed for a standard process evaluation (complete input data must be delivered according to specifications defined). If necessary, definition of the input data can be assisted. The other types of processes can be verified via computer simulation, please contact our consultants for more details. All data are treated as strictly confidential.